Volkswagen’s 2026 reset: New designs, hybrid focus, and high stakes

A revised approach to the way the company does business hopes to alleviate some of its recent challenges

It’s a tough time for the German carmaker right now. North American leadership just saw a management shuffle while overseas, it faces plant closures, wage cuts, and layoffs to save billions of dollars in response to converging economic pressures.

But all is not lost, as Kai Grünitz, VW’s point person for Research & Development, explained to Autocar magazine at the LA Auto Show. The company's new plan begins with a revamp of the company’s all-electric lineup, with changes made to the Modular Electric (MEB) platform that supports vehicles like the ID.4 and the just-launched ID. Buzz van.

It all starts with new designs

Volkswagen

“Huge improvements” would be coming to the EV platform, including a new aesthetic that would see Volkswagen “going back to where we came from,” said Grünitz. He’s inclined to create a new design language, and then implement it to make it a “loved brand” once more.

The revamp begins with the ID.2all, which debuted in 2023 as a concept inclined for production in 2025. That may not be happening as scheduled though, as one of the economic pressures VW faces is slowing EV demand. However, the Golf-sized EV model is still expected to launch as part of the updated MEB platform, followed by an SUV. Grünitz confirms this unnamed SUV will launch at the Munich Motor Show in Sept. 2025 with new styling cues. To achieve this, it will get software help from Rivian which has entered a joint venture to develop Volkswagen’s next EVs.

Related: A nostalgic look at Hyundai’s lost icons

The new design language doesn’t apply to just EVs, but gasoline-powered vehicles as well. New European regulations for emissions will slim down ICE offerings, though mild hybrid options are still in the cards.

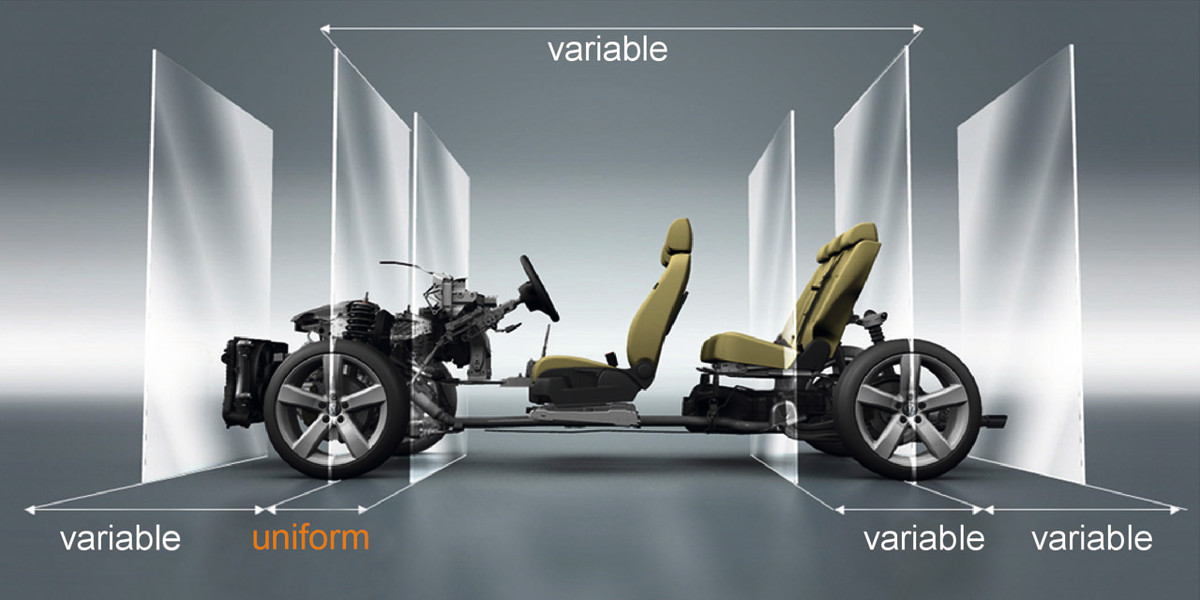

The potential for full hybrid variants may lie with the Scalable Systems Platform (SSP), as the goal of that platform is to underpin every type of vehicle Volkswagen offers. The 2026 launch of the first SSP-supported model has already been pushed back due to software issues, and revising MEB to improve the appeal of all-electric cars may push it back further.

VW will have to rethink their platform development

Volkswagen

SSP will also be responsible for cutting down the costs of electric cars, making them more affordable but still profitable for the company. This will be done through standardizing parts to fit and share across multiple economies of scale, which is how the platform will accommodate every type of vehicle, regardless of size.

Despite the 2025 Volkswagen Tiguan debuting without a hybrid setup, the Director of Public Relations and Reputation for Volkswagen Group of America, Mark Gilles, said the company is considering hybrids, noting that “being late on hybrids might actually be a good thing.” On the flip side, the new Tiguan features design details that hadn’t yet appeared on other VW models, giving a possible preview of what’s coming soon.

Related: Rivian CEO slams dealership laws: "It’s close to corruption"

The R&D boss also elaborated on investing in parallel architectures, not just MEB but Volkswagen’s ICE-friendly MQB platform that supports current models like the Golf GTI and Golf R. The launch of the third-generation Tiguan means MQB has extended its lifespan, as Grünitz said there’s no end date yet, again referring to the waning popularity of EVs. For now, gasoline-powered VWs are here to stay.

Final thoughts

Volkswagen needs a break. It seems to have never fully recovered from Dieselgate of the mid-2010s, and now we’re learning that its local workforce is preparing to strike in December amid talks between the local labor leaders and management.

Workers are affected by VW’s decision to close three factories in native Germany, an unprecedented move never done before in the company’s 87-year history. How the company responds to union pressure may alter the company’s legacy forever.

Whether this affects the new Tiguan remains to be seen as this is the brand’s bestselling model globally. Currently, the final assembly point for Tiguans sold in the U.S. is located in Chattanooga, Tennessee. Its success may hang on the outcome if corporate Volkswagen can strike a deal with its plant workers. The coming weeks may provide the answer.

Related: Trump’s proposed tariffs could reshape the auto industry