Dreams of a General Lee Lead to a Modern Pro-Touring Charger Project

If ever there was a TV show that inflicted its viewers with an enduring admiration for a certain muscle car, without a doubt, that show is the southern-situated, action-comedy series, “The Dukes of Hazzard,” which debuted in 1979. Those poor Duke Boys were constantly being harassed by local law enforcement, just because they rode around… The post Dreams of a General Lee Lead to a Modern Pro-Touring Charger Project appeared first on The Online Automotive Marketplace.

If ever there was a TV show that inflicted its viewers with an enduring admiration for a certain muscle car, without a doubt, that show is the southern-situated, action-comedy series, “The Dukes of Hazzard,” which debuted in 1979. Those poor Duke Boys were constantly being harassed by local law enforcement, just because they rode around in what was supposed to be a mildly tamed stock car. Well, maybe also because they’d dabbled a little in the bootleg liquor trade in their past. Well, that and a few other things, but man, the Duke boys’ ’69 Dodge Charger, dubbed “The General Lee,” was a hero car for the ages, and the image of that bright orange Mopar was burned deeply into the cerebrums of many budding young hot rodders who dutifully tuned in every Friday night.

One of those young guns who fell under the spell of the Duke Boys’ Dixie-tooting Dodge was Ken Jones of Knoxville, Maryland. “I was hooked on the General Lee after watching the Dukes of Hazzard while growing up. It was just amazing, seeing one of the coolest (and largest) muscle cars slinging dirt, outrunning the law, and of course, making those jumps. So, it was the second-generation Charger that just did it for me. It was the Charger’s aggressive looks and ‘Coke-bottle’ design that really drew me in,” Ken states.

Even at an early age, Ken was no stranger to the mechanics of American muscle cars. “In high school I worked at my friend Dave’s restoration shop through the summers and even during hours off from school. There I learned the basics of restoring classic and muscle cars. Lots of welding, installing patch panels, basic body work, and mechanical work,” Ken says, explaining that, “This is where my love and automotive passion was fueled, and I knew that one day that I would have my dream car: a 1968 Dodge Charger.”

While working at his buddy’s shop, Ken owned and drove several future classics, using them as daily drivers while he finished school. “Before I could legally drink, I’d had a C10 pickup, a ’61 Mercury, and a V-8-swapped Ford Ranger, as well as some others.” However, there was a voice of reason back then, and it came in the form of Ken’s girlfriend (and future wife), Ashley. “She would ask me, just before I bought yet another project car, ‘Why don’t you get your dream car?’ And so that’s what I finally did.”

So, Ken hit the internet, and before long, he found what he was looking for on a popular marketplace website. “I spotted a ’68 Charger and messaged the owner, this guy named Chris. I drove out there that day and looked at the car. It was your typical barn-find situation. It was in an old barn and was surrounded by old parts and all that random garage storage stuff. We made a deal on the spot and a week later I drove out and brought it home.”

However, after getting the Charger home, reactions were less than encouraging. “I’ll never forget the number of friends and family questioning my decision at the time. The car was so rusty that it had no rear frame rails left, and the leaf springs were sticking through the trunk pan. I could see why they were skeptical, but I never had a doubt that I could make this all work.”

Undaunted, Ken immediately got to work on his new-to-him B-body. He quickly put his skills to good use and fabricated a frame jig to hold the eviscerated body until he could work his magic and shore up its unibody structure. From there, much of the original sheetmetal was cut away to make room for a fresh skin. “Amazingly, the only original piece of the car that was left was the roof! I bought multiple shipments of AMD sheetmetal and began reading forums and watching YouTube videos to figure out how to get out of the predicament I put myself in.”

During the process, Ken even had to buy a donor Dodge Coronet to get some more of the parts he needed, including the front frame rails. He even built up the body with a frame-bracing kit from USCT Motorsports. It took time, but Ken pushed forward, aided by his knowledge of muscle car fabrication, and the fact that he couldn’t let this “holey” Charger beat him. “Luckily, within a couple of years, the car was welded back together, and all panel gaps were then fine-tuned to a perfectionist’s standards. It was a total success in my book.”

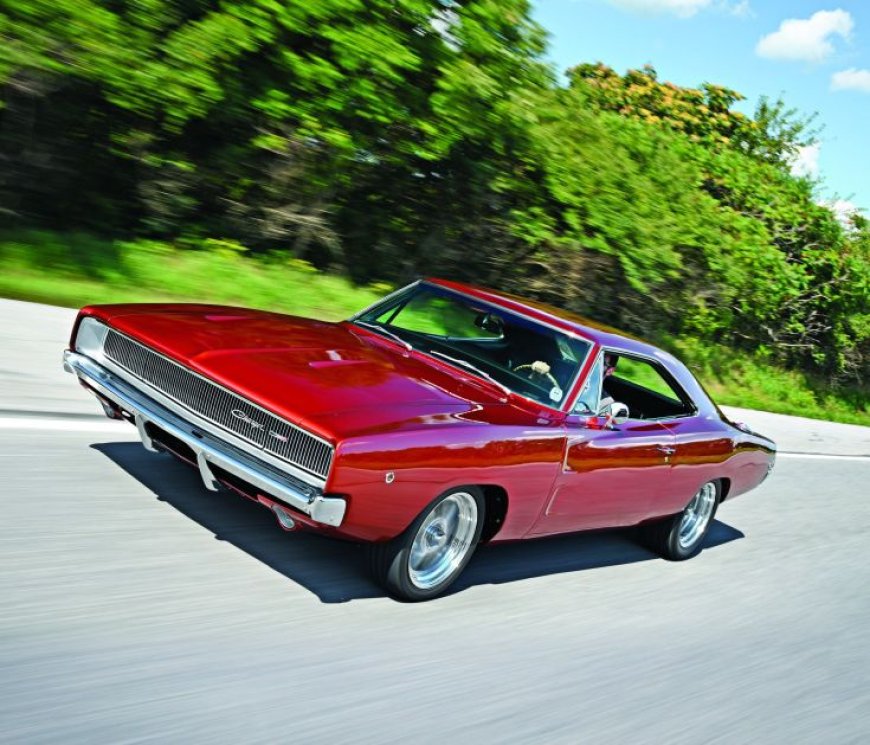

Next, the Charger made a visit to the place where Ken had held his summer job during his high school years. Dave Cornwell at DC Hot Rods in Laurel, Maryland took the Charger in and finished off the body work, getting the flanks laser straight before skinning the Dodge in House of Kolor Kandy Tangerine. The paint job speaks for itself, and really sets off the lines of the Charger.

While that was going on, Ken focused on collecting every part he would need to get this muscle car on the road. What he couldn’t find, he ordered out of the numerous online catalogs. Then he turned his thoughts to what was eventually going to power the Charger down the road. “Seeing that it was a 383/727 combination from the factory and knowing the original drivetrain was long gone, I thought about how to get more power. The obvious answer seemed to be a newer Hemi.”

Ken then punched that ticket and scored himself a powertrain from a wrecked 2018 Challenger Scat Pack. “The Challenger was a low-mileage car and was in good shape. I tore it down and got to work boosting its performance.” He did that by adding a hefty Texas Speed camshaft kit to give the Gen III 392 a little more rumble and an extended power curve. A Holley Terminator X-Max ECU controls engine management, enabling the transplant. The new engine bolted right up to the upgraded QA-1 tubular K-member Ken purchased. This setup adds rigidity up front, lightens the load, and makes it easy to swap in modern drivetrains.

From there, Ken welded in a USCT transmission tunnel so he could mount install the massive Tremec TR-6060 six-speed manual transmission that was enlisted for shifting duties. Along with the QA-1 K-member, Ken used that company’s full suspension package up front, which included a QA-1 Mopar B-body handling kit that works in conjunction with the original torsion-bar set-up. The kit includes tubular upper and lower control arms, dynamic strut bars, single-adjustable front and rear shocks, and a front anti-sway bar. Ken achieved his stance by adding Calvert Racing 2-inch drop leaf springs out back with 2-inch lowering blocks. Up front, he brought the nose down by backing off on the torsion-bar adjusters.

The Charger’s power output is sent out back to a Strange Engineering Dana 60 built with an Eaton Truetrac differential and stuffed with 4.10 gears. Wilwood disc brakes with four-piston calipers and slotted rotors are stationed at the corners, aided by a Hydro-Boost set-up, which helps this long and lean Mopar to stop on a dime. Ken added power steering up front by using an upgraded Borgeson steering box, fed by a retrofit Holley power steering pump. Calvert Racing CalTracs traction bars help keep the axle from rotating, maintain pinion angle, and aid launch traction.

When it came to the interior, Ken ordered a complete upholstery kit from Legendary Interiors in its original black vinyl. To keep track of the vitals he chose a set of Dakota Digital Rallye gauges. A Vintage Air unit helps with climate control, especially on those hot Maryland summer days. For tunes, Ken decided on the Retrosound unit to keep a period-correct appearance while improving sound quality.

With its updated powertrain and upgraded suspension and brakes, Ken’s Charger project was clearly aimed at a Pro-Touring-style outcome, and to that end, Ken selected Billet Specialties 17-inch Street Lite wheels wrapped in Firestone Firehawk performance rubber. A Cold Case radiator keeps the Charger cool on the hottest of days, helped by Derale electric fans. One extra add-on was the electric actuator headlight conversion up front, which replaced the often-dysfunctional OEM vacuum units.

Ken beams when discussing the finished project. “I can’t say enough about the performance and reliability of the 392 Hemi. With a click of the key, it fires up and idles in traffic with the A/C on full blast and has plenty of rumble from that Texas Speed cam. It’s just an overall blast to drive with the 500-plus horsepower the Hemi offers when mated to the manual six-speed. The Holley ECU plugging right into the Dakota gauges made that part of the conversion nearly effortless; I can even use the app on my phone. It handles so well with the modern suspension upgrades, minimal body roll and modern braking that I feel comfortable throwing the car seat in the back and taking the family out cruising with me.”

Projects like this obviously take a lot of dedication, along with plenty of time, effort and money. But the support to make it to the end is critical, and for this Charger, Ken credits the one who originally encouraged him to get his dream car: his wife, Ashley. “I couldn’t have done it without her support.”

Specifications – 1968 Dodge Charger

ENGINE

Block type: Chrysler Gen III OHV Hemi V-8, cast-iron

Cylinder heads: Chrysler Gen III Hemi, aluminum, 2.14/1.65-in valves, intake/exhaust

Displacement: 6.4-liters (392 cubic inches)

Bore x stroke: 4.09 x 3.72

Compression Ratio: 10.9:1

Horsepower @ rpm: 485 @ 6,100 (Stock; with cam change, 500+ est.)

Torque @ rpm: 475@ 4,200

Camshaft: Texas Speed hydraulic roller

Induction system: Stock 392 composite manifold with port-injection and 80-mm throttle body

Exhaust system: Hooker tubular headers with Holley 3-inch exhaust system

Engine management system: Holley Terminator X ECU

TRANSMISSION

Type: Tremec TR-6060 six-speed manual

Ratios: 1st/2.97:1…2nd/2.10:1…3rd/1.46:1…4th/1.00:1…5th/0.74:1…6th/0.50:1…Reverse/3.28:1

DIFFERENTIAL

Type: Strange Engineering Dana 60 with Eaton Truetrac

Ratio: 4.10:1

STEERING

Type: Borgeson recirculating-ball gearbox with Holley power steering pump

Ratio: 14:1

BRAKES

Type: Hydraulic four-wheel disc

Front/Rear: Wilwood four-piston calipers with slotted rotors

SUSPENSION

Front: QA-1 tubular upper and lower control arms with single-adjustable shocks with stock Chrysler torsion bars, Dynamic strut bar, QA-1 front sway bar

Rear: QA-1 single-adjustable shocks, Calvert 2-in drop leaf springs, 2-in lowering blocks, and CalTracs traction bars

WHEELS & TIRES

Wheels: Billet Specialty Street Lite aluminum

Front: 17 x 7 inches

Rear: 17 x 10 inches

Tires

Front: Firestone Firehawk 500 225/45R17

Rear: Nitto NT555 275/50R17

PERFORMANCE

Untested

The post Dreams of a General Lee Lead to a Modern Pro-Touring Charger Project appeared first on The Online Automotive Marketplace.